The Template

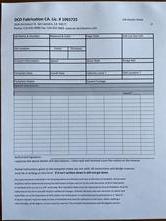

It is our standard operating procedure to set template appointments between 9:00 -11:00 or between 1:00 - 3:00. The office will send a reminder text to the contact number provided a day or two before the appointment. The template maker will text with a more precise arrival time on the day of the appointment. The template is perhaps the most crucial step in the process. It is important that someone with intimate knowledge of the project be present for the template. The countertop area must be free of debris, tools, food, appliances, etcetera. A “detail sheet” is created during the template process. The information noted on the “detail sheet” at the template appointment along with the physical template is what we use to guide the fabrication. The responsible onsite person is asked to initial and sign the “detail sheet” at the template appointment. The onsite person is left with a yellow carbon copy of the detail sheet which includes the install date. During the quoting process, there may be many quote revisions with different materials, different edges, etcetera. There may be emails or text messages months earlier about some aspect of the job. There may also be design questions or options to determine during the template appointment. All that information must be discussed with the template maker and transferred to the “detail sheet” during the template appointment. That is why it is so important that a knowledgable and responsible person is present at the time of template to insure that all pertinent information is included and correct. If it is not on the detail sheet, it is not going to happen. This bid is based on measurements and drawings provided and the interpretation of DCD staff. Actual square footage and scope of work will be verified after template. Any significant discrepancy between the bid estimates and the actual template will be brought to the attention of the showroom / contractor. Any changes that affect billing will generate a change order which must be approved before the job can proceed. A standard size kitchen will typically take 2 hours to template. The template maker will take photos to memorialize the condition of he site at the time of template as well as the completed template. We do this to protect all involved from erroneous claims of damage or claims that a countertop was not fabricated according to the template. | Ready for Template

Ready for template means that the cabinets are installed level, plumb, and straight. The plywood sub top (if applicable) has been installed. 5/8” or 3/4” plywood should be flush with the cabinet face. The under mount sink is dropped into the plywood hanging from the sink lip. The hole should be about 1/2” bigger than the sink so that there is plenty of wiggle room.

| Sink in the Plywood

Why do we ask that an under mount sink be dropped into the plywood before template? It insures that the sink is not damaged, that the sink fits in the sink cabinet, that there is enough room for the faucet and splash, that there are no obstructions like plumbing or hinges. If we wait to discover these types of issues at the time of template, it will cause delays and could result in additional charges. If the sink is dropped into the plywood prior to the template, any such issues can be addressed before the template appointment saving time and money.

|

Standard Under Mount Sink Cutout

FYI - With a standard under mount sink cutout, the stone overhangs the lip of the sink approximately 1/4”. The “setback” is measured from the finished countertop edge to the front of the sink cutout. The standard setback is 3”-4”. The Physical Template

A physical template will be made which represents the finished countertop edges. The wooden template is essential for our fabrication process but also a great visual aid for the on site person. It offers an opportunity to see where and how the countertop will be installed. The wooden template notates the finished edges, the edge style, the sink center, the probable seam locations (actual seam locations are determined at the discretion of DCD), the job name, the material name and other information. The responsible onsite person has an opportunity to review the wooden template, ask questions and make design decisions. When making the template we follow the plywood. We measure the countertop overhang from the cabinet face not the drawer face. FYI - a standard overhang using a mitered edge is 1-1/4”. A standard overhang using laminated edges like Bullnose is 1-1/2” | Standard Under Mount Sink Cutout

FYI - With a standard under mount sink cutout, the stone overhangs the lip of the sink approximately 1/4”. The “setback” is measured from the finished countertop edge to the front of the sink cutout. The standard setback is 3”-4”. The Physical Template

A physical template will be made which represents the finished countertop edges. The wooden template is essential for our fabrication process but also a great visual aid for the on site person. It offers an opportunity to see where and how the countertop will be installed. The wooden template notates the finished edges, the edge style, the sink center, the probable seam locations (actual seam locations are determined at the discretion of DCD), the job name, the material name and other information. The responsible onsite person has an opportunity to review the wooden template, ask questions and make design decisions. When making the template we follow the plywood. We measure the countertop overhang from the cabinet face not the drawer face. FYI - a standard overhang using a mitered edge is 1-1/4”. A standard overhang using laminated edges like Bullnose is 1-1/2” | Standard Under Mount Sink Cutout

FYI - With a standard under mount sink cutout, the stone overhangs the lip of the sink approximately 1/4”. The “setback” is measured from the finished countertop edge to the front of the sink cutout. The standard setback is 3”-4”. The Physical Template

A physical template will be made which represents the finished countertop edges. The wooden template is essential for our fabrication process but also a great visual aid for the on site person. It offers an opportunity to see where and how the countertop will be installed. The wooden template notates the finished edges, the edge style, the sink center, the probable seam locations (actual seam locations are determined at the discretion of DCD), the job name, the material name and other information. The responsible onsite person has an opportunity to review the wooden template, ask questions and make design decisions. When making the template we follow the plywood. We measure the countertop overhang from the cabinet face not the drawer face. FYI - a standard overhang using a mitered edge is 1-1/4”. A standard overhang using laminated edges like Bullnose is 1-1/2” | Standard Under Mount Sink Cutout

FYI - With a standard under mount sink cutout, the stone overhangs the lip of the sink approximately 1/4”. The “setback” is measured from the finished countertop edge to the front of the sink cutout. The standard setback is 3”-4”. The Physical Template

A physical template will be made which represents the finished countertop edges. The wooden template is essential for our fabrication process but also a great visual aid for the on site person. It offers an opportunity to see where and how the countertop will be installed. The wooden template notates the finished edges, the edge style, the sink center, the probable seam locations (actual seam locations are determined at the discretion of DCD), the job name, the material name and other information. The responsible onsite person has an opportunity to review the wooden template, ask questions and make design decisions. When making the template we follow the plywood. We measure the countertop overhang from the cabinet face not the drawer face. FYI - a standard overhang using a mitered edge is 1-1/4”. A standard overhang using laminated edges like Bullnose is 1-1/2” |

Standard Under Mount Sink Cutout

FYI - With a standard under mount sink cutout, the stone overhangs the lip of the sink approximately 1/4”. The “setback” is measured from the finished countertop edge to the front of the sink cutout. The standard setback is 3”-4”. The Physical Template

A physical template will be made which represents the finished countertop edges. The wooden template is essential for our fabrication process but also a great visual aid for the on site person. It offers an opportunity to see where and how the countertop will be installed. The wooden template notates the finished edges, the edge style, the sink center, the probable seam locations (actual seam locations are determined at the discretion of DCD), the job name, the material name and other information. The responsible onsite person has an opportunity to review the wooden template, ask questions and make design decisions. When making the template we follow the plywood. We measure the countertop overhang from the cabinet face not the drawer face. FYI - a standard overhang using a mitered edge is 1-1/4”. A standard overhang using laminated edges like Bullnose is 1-1/2” |

|